Зміст

Вступ

Спіральні щітки є незамінними інструментами в різних галузях промисловості завдяки своїй винятковій універсальності. Незалежно від того, чи ви очищаєте делікатне обладнання, знімаєте задирки з деталей чи обробляєте шорсткі поверхні, ці щітки забезпечують ефективне та результативне рішення. Завдяки своїй здатності адаптуватися до різних форм і розмірів, спіральні щітки ідеально підходять для завдань, що вимагають точності та гнучкості.

In this comprehensive guide, we’ll dive deep into the world of spiral brushes, explaining their construction, types, applications, and how to choose the perfect one for your specific needs. By the end of this article, you’ll have a clear understanding of what spiral brushes can do and how to use them to achieve outstanding results in your work.

What Are Spiral Brushes?

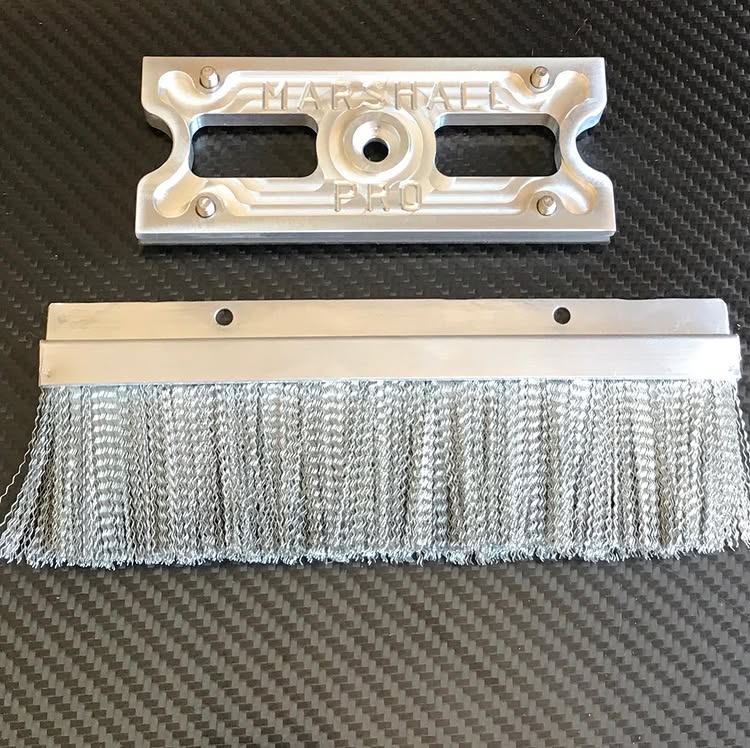

Spiral brushes are rotary brushes designed with a twisted filament arrangement. Their helical shape enables them to conform to irregular surfaces and handle complex shapes, which makes them ideal for a wide range of tasks. These brushes come in several sizes and materials, including nylon, brass, stainless steel, and even abrasive-filled nylon, offering great flexibility for different applications.

The spiral design ensures that the brush bristles are flexible yet durable, allowing them to reach tight spaces and clean intricate parts that traditional brushes cannot. Their unique construction also makes them effective in both light-duty and heavy-duty tasks, including cleaning, dusting, deburring, and polishing.

The primary advantage of spiral brushes lies in their ability to clean hard-to-reach areas. Thanks to their twisted bristles, these brushes can bend and conform to complex geometries, allowing you to effectively clean gears, pipes, tubes, cylinders, and other machinery components that would be challenging with standard brushes.

Types of Spiral Brushes

Spiral brushes come in three main variations, each offering distinct features suitable for specific applications:

1. Single-Stem Spiral Brushes

Single-stem brushes have a straight stem with bristles wrapped around it. These are commonly used for light cleaning tasks and are best suited for narrow, confined spaces.

2. Double-Stem Spiral Brushes

Double-stem brushes feature two twisted stems, each with bristles wound around them. This design offers enhanced durability and cleaning performance, making them ideal for more demanding tasks such as deburring and heavy-duty cleaning.

3. Twisted Wire Spiral Brushes

Twisted wire spiral brushes use wire bristles that are twisted together to form the stem. These brushes are particularly effective in harsh conditions where you need a more robust and rigid tool for tasks like rust removal, surface preparation, and polishing.

Each type of spiral brush has its advantages and is suited for different industrial needs. Understanding the differences will help you choose the right brush for your application.

Common Applications of Spiral Brushes

Spiral brushes are used in a wide array of applications, thanks to their adaptability and efficiency. Here are some of the most common uses:

1. Surface Finishing

Spiral brushes with abrasive-filled bristles are highly effective for surface finishing. They can be used to smooth rough edges, remove burrs, and create an even surface texture. This makes them ideal for industries like manufacturing, where smooth and polished surfaces are essential.

2. Deburring

For removing metal burrs from machine parts, twisted wire spiral brushes are a top choice. The rigid wire bristles help clean sharp edges and excess material that might affect the functionality of machinery. This application is crucial in metalworking and fabrication.

3. Cleaning

Spiral brushes are often used for cleaning intricate parts of machinery, such as gears, pipes, and cylinders. The flexibility of the bristles enables them to reach tight spaces, removing dirt, dust, and debris that other cleaning tools can’t access.

4. Polishing

Brass spiral brushes are perfect for polishing metal surfaces. Their soft bristles gently buff away oxidation and create a shiny, smooth finish, which is often required in industries that deal with metal products, jewelry, or automotive parts.

How to Choose the Right Spiral Brush

Selecting the appropriate spiral brush for your task is essential to achieving the best results. Here are some key factors to consider when choosing a spiral brush:

1. Material

The material of the bristles is a crucial factor. Nylon bristles are great for light cleaning tasks, while brass is often used for polishing. Stainless steel bristles are ideal for tougher tasks, such as deburring and rust removal, while abrasive-filled nylon works best for surface finishing.

2. Brush Type

Depending on the task at hand, you may need a single-stem, double-stem, or twisted wire brush. Single-stem brushes are suitable for light-duty cleaning, while double-stem and twisted wire brushes are better for heavy-duty applications.

3. Bristle Density

The density of the bristles affects the brush’s cleaning power. A high-density brush offers more surface contact, making it ideal for heavy-duty cleaning, deburring, and polishing, while lower-density brushes are better for delicate tasks.

4. Filament Diameter

The diameter of the filaments influences the stiffness of the brush. A larger diameter is suitable for tougher cleaning tasks, while smaller diameters are ideal for finer cleaning and polishing.

5. Rotation Speed and Torque

Consider the required rotation speed and torque for your application. Some spiral brushes are designed to operate at higher speeds, making them ideal for quick cleaning, while others are better suited for low-speed, high-torque tasks, such as deburring and polishing.

Maintaining Spiral Brushes

Proper maintenance is essential to ensure the longevity and optimal performance of spiral brushes. Regular cleaning helps prevent the buildup of debris and dust in the bristles, which could reduce their effectiveness. Additionally, avoid overworking the brush, as excessive wear can cause the bristles to lose their shape and performance.

When the bristles begin to show signs of wear, it’s important to replace the brush promptly to maintain efficiency and achieve the desired results.

Висновок

Spiral brushes are indispensable tools for a wide range of tasks, from cleaning and polishing to deburring and surface finishing. Understanding the types of spiral brushes, their materials, and their applications is key to choosing the right tool for your needs. Regular maintenance will also ensure that your spiral brushes continue to perform optimally over time, saving you time and money in the long run.

By selecting the right spiral brush and following proper maintenance practices, you can achieve outstanding results in various industrial processes, enhancing your workflow and product quality.

Найчастіші запитання

1. What materials are spiral brushes typically made from?

Spiral brushes are commonly made from materials such as nylon, brass, stainless steel, and abrasive-filled nylon, each offering unique benefits depending on the application.

2. How do I know which type of spiral brush to use for my task?

The choice of spiral brush depends on the nature of the task. Single-stem brushes are best for light cleaning, double-stem brushes are ideal for heavy-duty applications, and twisted wire brushes are perfect for deburring and rust removal.

3. How can I maintain the performance of my spiral brush?

Regular cleaning is key to maintaining the brush’s effectiveness. Avoid overworking the brush, and replace the bristles when they become worn to ensure optimal performance in your applications.