Turinys

When it comes to heavy-duty cleaning and surface preparation, a wire brush for a drill is an indispensable tool in any toolbox. Whether you are a professional contractor, metalworker, or DIY enthusiast, understanding the uses and advantages of a wire brush attachment can help you achieve better results in your projects. This article will explore what a wire brush for a drill is used for, how it works, the different types available, and best practices for using it safely and effectively.

Understanding the Wire Brush for a Drill

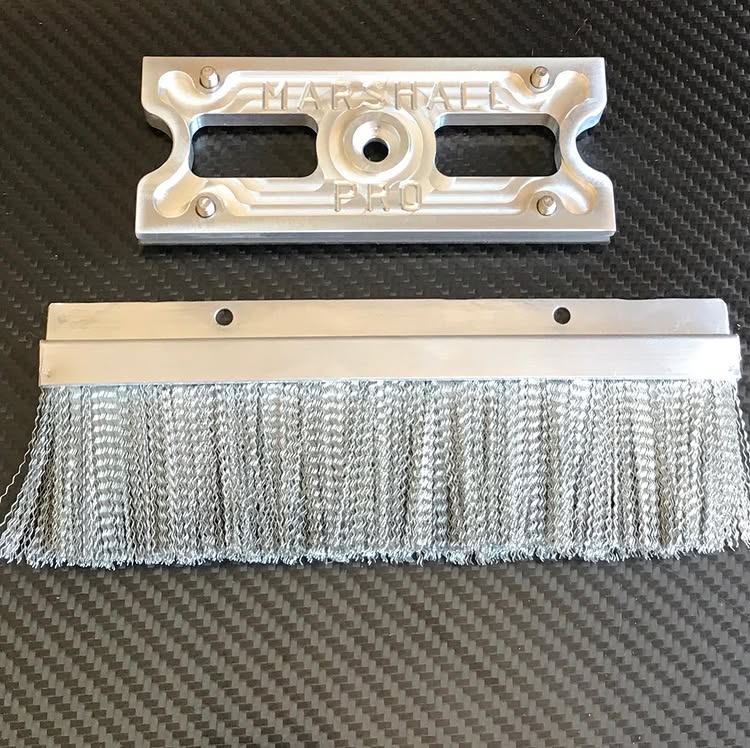

A wire brush for a drill is an attachment made of steel, brass, or stainless steel wires fixed to a spindle or base. It can be round, cup-shaped, or in a wheel configuration and is designed to be attached to a power drill. Once mounted, the rotating action of the drill gives the brush the speed and force needed to perform a variety of cleaning and surface preparation tasks. It is a highly versatile tool that can handle both delicate and aggressive applications depending on the wire material, thickness, and design.

Main Uses of a Wire Brush for a Drill

1. Removing Paint and Rust

One of the most common uses of a wire brush for a drill is removing paint and rust from metal surfaces. Over time, metal structures such as fences, tools, automotive parts, and furniture can become coated in layers of paint or corroded by rust. A wire brush drill attachment makes quick work of stripping away these unwanted layers, exposing clean metal beneath. This is especially useful in restoration projects, surface preparation before repainting, or preventing further corrosion.

2. Deburring Sharp Edges

After cutting or machining metal, the edges are often left with sharp burrs. These burrs can be hazardous and may interfere with the fit or finish of assembled parts. A wire brush for a drill is ideal for deburring, as it smooths these edges efficiently without significantly altering the shape or structure of the material. This makes it essential in metal fabrication and automotive repair tasks.

3. Edge Blending

Edge blending is the process of softening or smoothing the transition between two surfaces, especially in welds or joints. A wire brush for a drill excels at this task, allowing users to create clean, smooth transitions between materials. This not only improves the visual appeal of a workpiece but also enhances its structural integrity and safety.

4. Deep Cleaning Surfaces

Wire brushes are highly effective for deep cleaning a variety of surfaces. They can remove grease, grime, carbon deposits, oxidation, and other stubborn contaminants from metal, wood, and stone. Whether you’re cleaning a grill, engine block, or industrial equipment, a wire brush for a drill allows for detailed and efficient cleaning without the need for harsh chemicals.

5. Preparing Surfaces for Welding or Painting

Surface preparation is critical to the success of welding and painting projects. A wire brush drill attachment is frequently used to clean and roughen the surface, which improves paint adhesion and welding effectiveness. By removing oil, rust, and old coatings, the brush ensures that the new layer bonds well and performs as expected over time.

Types of Wire Brushes for Drills

There are several types of wire brushes for drills, each suited to specific tasks:

- Vieliniai diskiniai šepečiai: Ideal for flat surface cleaning, edge blending, and rust removal. Their disc shape makes them perfect for large surface areas.

- Vieliniai puodelio formos šepečiai: Best for heavy-duty cleaning and working on larger surfaces. The cup design allows for broader contact with the material.

- End Brushes: These are small and precise, used for cleaning tight spaces, holes, and corners. They are commonly used in automotive and machinery maintenance.

Wire material also matters. Steel wire is aggressive and suitable for rust and paint removal. Brass wire is softer and safer for non-ferrous metals, while stainless steel is corrosion-resistant and ideal for use on stainless surfaces.

Best Practices and Safety Tips

While using a wire brush for a drill is straightforward, there are important safety and operational guidelines to follow:

- Always wear protective eyewear, gloves, and long sleeves to guard against flying debris.

- Ensure the wire brush is properly secured in the drill chuck before use.

- Start the drill at a low speed to maintain control, especially when working on delicate materials.

- Do not press too hard. Let the wire brush do the work to avoid damaging the surface or causing premature brush wear.

- Inspect the brush regularly for wear, broken wires, or imbalance and replace it as needed.

Choosing the Right Wire Brush for Your Project

To get the best results, choose the appropriate type and size of wire brush for your specific application. For broad paint removal, a cup brush with steel wires is ideal. For precision work like cleaning a threaded hole or removing rust from a bolt, a small end brush with brass wires may be more appropriate. Consider the material you’re working on, the level of aggression required, and the area size before selecting your tool.

Išvada

A wire brush for a drill is a powerful, multi-purpose tool that adds incredible value to any workshop. From removing rust and paint to deburring sharp edges and deep cleaning, its applications are vast and essential. By understanding the various types of brushes, how to use them safely, and choosing the right one for your project, you can significantly enhance the quality and efficiency of your work. Investing in a good wire brush attachment ensures you’re always prepared for the toughest cleaning and preparation jobs.

Whether you’re restoring a vintage car, preparing metal for welding, or simply cleaning up old tools, the wire brush for a drill remains one of the most practical tools for both professionals and DIYers alike.