Sisällysluettelo

Johdanto

Wire wheel brushes are indispensable tools used across various industries, including metalworking, automotive, woodworking, and construction. These brushes are designed to clean, polish, deburr, and remove contaminants from surfaces with ease. Their versatile nature makes them suitable for everything from heavy-duty rust removal to delicate polishing tasks. However, like any tool, wire wheel brushes require proper handling, the right selection, and routine maintenance to maximize their effectiveness and ensure safety.

In this comprehensive guide, we will explore the different types of wire wheel brushes, their wide range of applications, key safety tips for use, and essential maintenance practices to help you get the most out of these powerful tools.

What are Wire Wheel Brushes?

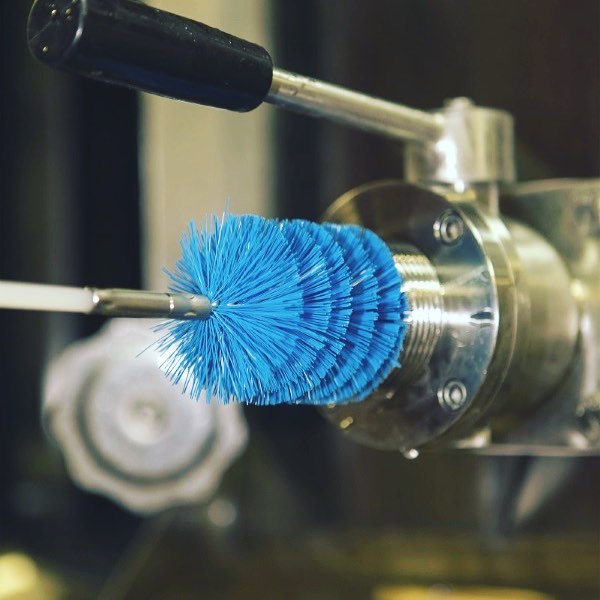

A wire wheel brush consists of wire bristles mounted on a central hub, which rotates at high speeds. The wire bristles come in various materials such as brass, carbon steel, stainless steel, and bronze, offering different advantages depending on the cleaning or polishing requirements. These brushes are available in a wide range of sizes, shapes, and stiffness levels to suit a variety of applications, from industrial tasks to home improvement projects.

Wire wheel brushes can be used for tasks such as removing rust, cleaning metal surfaces, deburring sharp edges, smoothing rough spots, polishing metals, and blending welds. However, the wrong type of wire brush or improper handling can cause accidents, injuries, or surface damage, so it’s essential to choose the right brush and handle it safely.

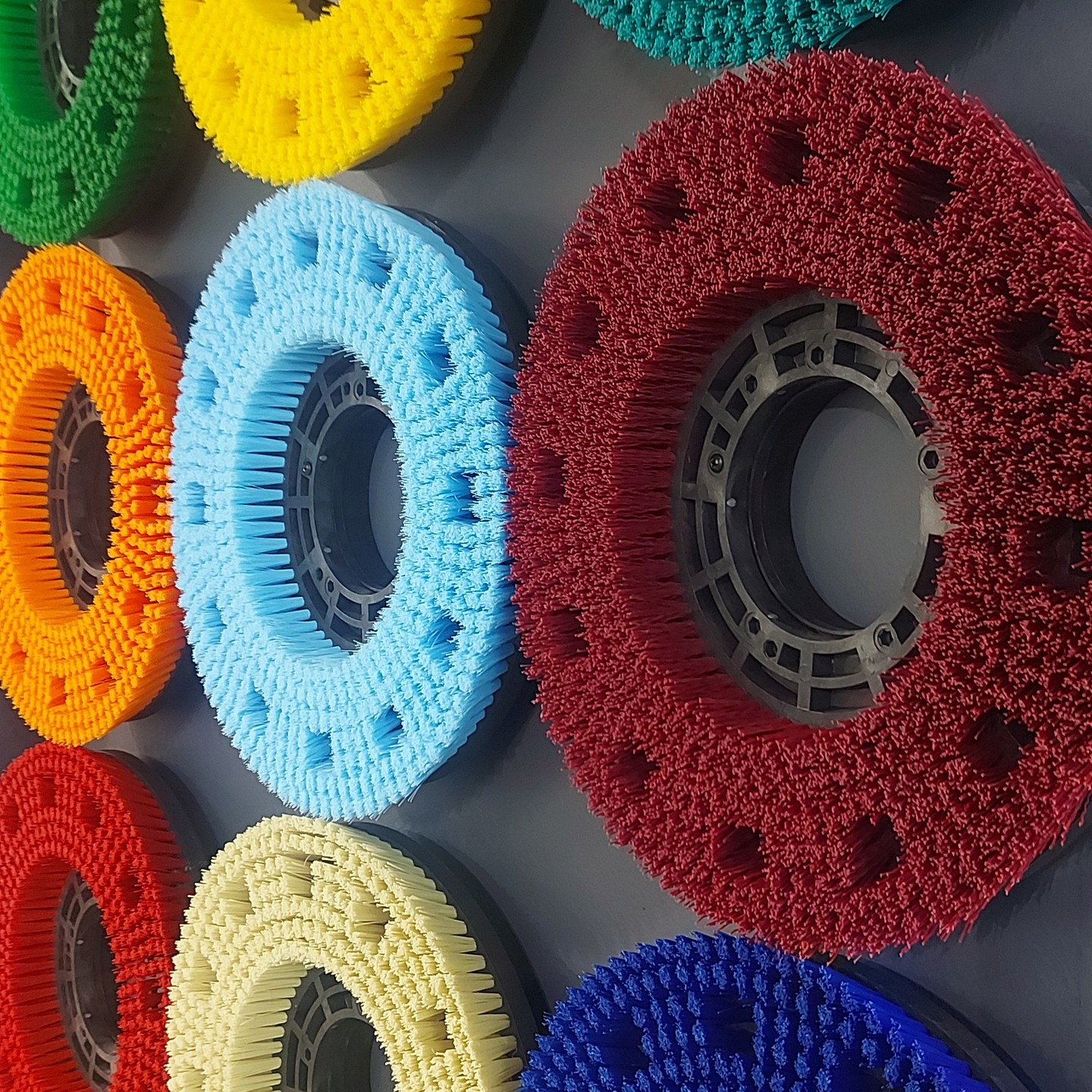

Types of Wire Wheel Brushes

Wire wheel brushes come in different styles and configurations, each designed for specific tasks. Choosing the right brush for the job is key to achieving the desired result while maintaining safety. Here are the most common types of wire wheel brushes:

1. Crimped Wire Brushes

Crimped wire brushes have wire bristles that are bent in a wavy or zigzagged pattern. This crimping gives the brush a flexible and light brushing action, making it ideal for light-duty cleaning tasks. These brushes are perfect for deburring, finishing, or polishing flat or curved surfaces without causing scratches or gouges.

Uses: Cleaning light rust, smoothing surfaces, and finishing welds.

2. Knotted Wire Brushes

Knotted wire brushes are designed with wire bristles twisted or braided into tight knots. This construction results in a stiff and aggressive brushing action, making these brushes ideal for heavy-duty cleaning, such as rust and scale removal. They are excellent for cleaning flat, irregular, or rough surfaces and are also commonly used for weld cleaning, blending, and brushing weld joints.

Uses: Removing heavy rust, cleaning welds, and preparing surfaces for further work.

3. Stringer Bead Brushes

Stringer bead brushes feature narrow, elongated wire bristles that are arranged in a tight cluster. These brushes are designed for precision work and are commonly used for cleaning weld beads, edges, and corners. They are also effective in removing flux residues and spatter from welds, making them a favorite among metalworkers.

Uses: Polishing weld beads, cleaning spatter, and removing flux.

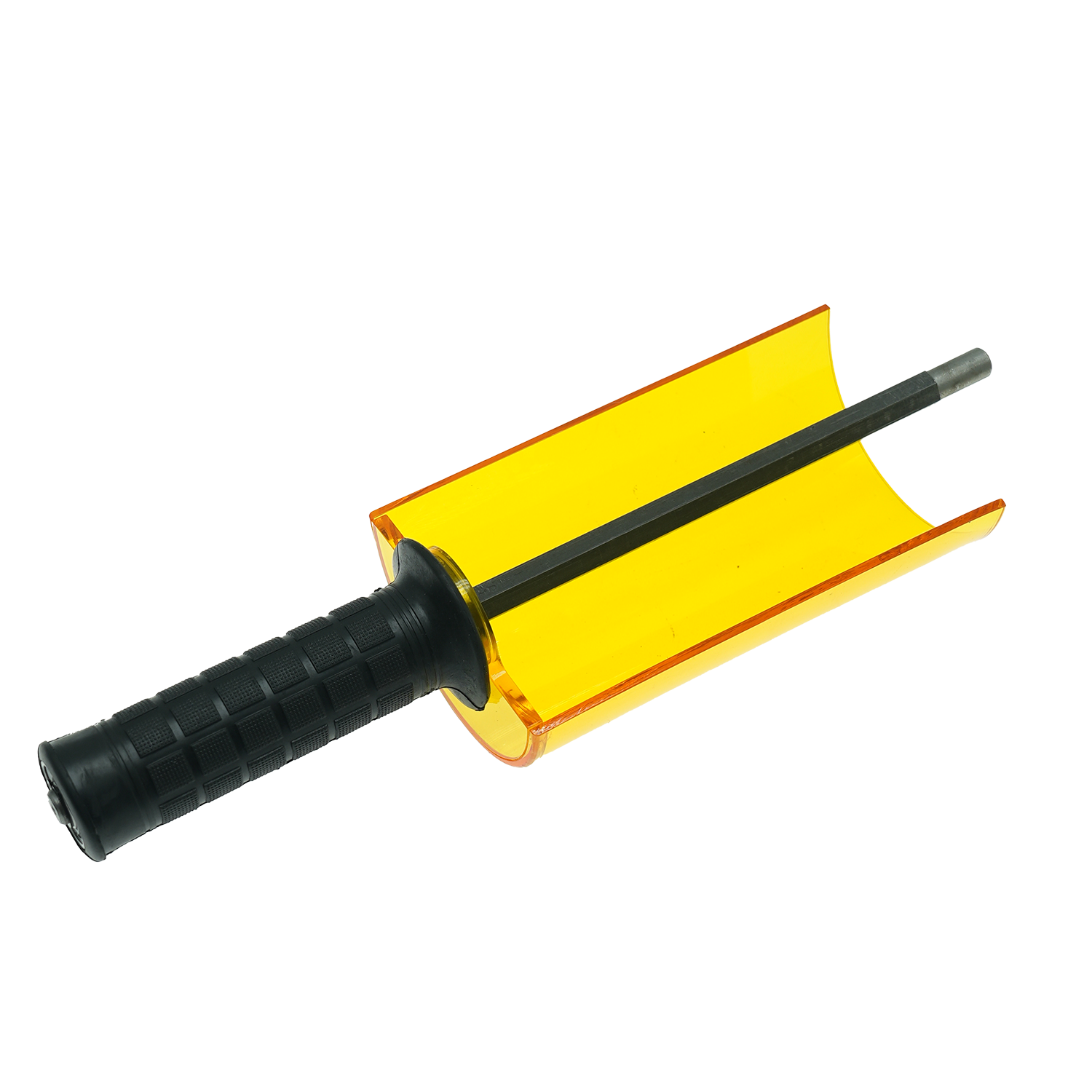

4. Stem-Mounted Brushes

Stem-mounted brushes have wire bristles attached to a stem or shank, allowing them to be mounted on a drill, rotary tool, or other power tools. These brushes are perfect for spot cleaning, blending, and finishing small, hard-to-reach areas. The stem-mounted design also allows for greater control and versatility when working on detailed projects.

Uses: Cleaning small areas, deburring, and polishing tight corners.

Applications of Wire Wheel Brushes

Wire wheel brushes are versatile and can be used in a wide range of industries and applications. Here are some of the most common uses:

1. Metalworking

In metalworking, wire wheel brushes are used to prepare metal surfaces for welding, painting, or coating. They are excellent for removing rust, paint, scale, and oxidation from metal surfaces. These brushes can also be used to blend welds, smooth rough edges, and polish metal to achieve a smooth, shiny finish.

Key Uses: Rust removal, surface preparation, polishing metals, and deburring.

2. Automotive

Wire wheel brushes are frequently used in automotive maintenance to clean brake components, engines, and other mechanical parts. They can also be used to remove carbon buildup, old gaskets, and undercoating from vehicle parts. Their ability to clean stubborn dirt, grime, and paint makes them a vital tool for automotive technicians.

Key Uses: Cleaning brake components, removing carbon buildup, and cleaning transmission parts.

3. Construction

In construction, wire wheel brushes are used to clean concrete, brick, and stone surfaces. They are particularly useful for removing mortar, grout, and rust from metal structures, ensuring that surfaces are ready for further treatment or painting. These brushes are also commonly used to clean and prepare the surfaces of scaffolding and other construction equipment.

Key Uses: Cleaning concrete, removing rust from metal structures, and preparing surfaces for painting.

4. Woodworking

Wire wheel brushes can also be used in woodworking to sand, smooth, and texture wood surfaces. They are excellent for removing glue, paint, and varnish from wood surfaces. Additionally, they can help create a textured finish or prepare wood for further treatment.

Key Uses: Removing paint, sanding, and texturing wood surfaces.

Essential Safety Tips for Using Wire Wheel Brushes

Wire wheel brushes are powerful tools, but they can be hazardous if not used correctly. To prevent accidents and ensure your safety, follow these essential tips when working with wire wheel brushes:

1. Protect Yourself with Safety Gear

Always wear proper personal protective equipment (PPE) when using wire wheel brushes. This includes safety glasses or goggles, gloves, and long-sleeved clothing to protect yourself from flying debris, wire bristles, or sparks. If you’re using a wire wheel brush on a power tool, consider wearing a face shield for additional protection.

2. Choose the Correct Brush for the Task

Selecting the right type of wire wheel brush is crucial. Ensure that the brush you use is suited to the material you are working on and the type of task at hand. A crimped brush is ideal for light cleaning and polishing, while a knotted wire brush is better for heavy-duty tasks like rust removal.

3. Maintain a Safe Distance

Always maintain a safe distance from the rotating brush. Never touch the brush while it’s spinning, and avoid reaching over or around the brush. Using a handle or extension tool to grip the brush can help ensure that you stay at a safe distance from the rotating bristles.

4. Do Not Exceed the Maximum Speed

Each wire wheel brush has a maximum operating speed, which should not be exceeded. Operating a wire brush at excessive speeds can cause it to break apart, creating a safety hazard. Always check the manufacturer’s specifications and ensure that your power tool is set to the appropriate speed.

5. Secure the Workpiece

Make sure that the workpiece is securely fastened or clamped to prevent it from moving or flying off during brushing. A loose workpiece can cause accidents and damage.

6. Avoid Using on Delicate Materials

Wire wheel brushes can be too aggressive for delicate materials such as glass, ceramics, or some plastics, which may crack or shatter under the brush’s action. Always check that the material you’re working with is suitable for wire brush cleaning.

Proper Maintenance of Wire Wheel Brushes

To ensure that your wire wheel brushes continue to perform effectively, regular maintenance is essential. Here are some tips for cleaning, storing, and replacing your wire wheel brushes:

1. Puhdista jokaisen käyttökerran jälkeen

Always clean your wire wheel brush after each use to remove debris, dust, and buildup. You can use a wire brush, compressed air, or a degreaser to clean the bristles and hub. Keeping your brush clean will help prevent rust and corrosion and ensure longer service life.

2. Store in a Dry Place

Store your wire wheel brushes in a cool, dry place away from moisture, which can cause rust. Avoid leaving brushes exposed to the elements, and keep them in their original packaging or a storage container to prevent damage and contamination.

3. Inspect Before Use

Before each use, inspect your wire wheel brush for signs of wear or damage. Check the bristles for any loose or broken wires and ensure that the brush is securely mounted on the hub. Replace the brush if it shows signs of excessive wear or if it no longer performs as expected.

Johtopäätös

Wire wheel brushes are essential tools across many industries, offering versatility and power for tasks such as cleaning, polishing, and deburring. Whether you’re preparing metal surfaces for further work, cleaning automotive parts, or texturing wood, the right wire wheel brush can make the job faster and more efficient.

By understanding the different types of wire wheel brushes, their applications, and following proper safety and maintenance procedures, you can maximize their effectiveness while minimizing risks. With these tips, you’ll be well-equipped to handle any wire wheel brush task safely and successfully.

Usein kysytyt kysymykset (UKK)

1. How do I choose the right wire wheel brush for my project?

To select the right wire wheel brush, consider the type of material you’re working with and the task at hand. Crimped brushes are ideal for light cleaning and polishing, while knotted wire brushes are better for heavy-duty tasks like rust removal. Always match the brush type to your specific cleaning or finishing needs.

2. Can I use a wire wheel brush for cleaning wood?

Yes, wire wheel brushes can be used in woodworking to remove paint, glue, and varnish. They can also be used to smooth or texture wood surfaces. However, make sure to use the correct brush type and be cautious not to damage the wood.

3. How can I prolong the life of my wire wheel brush?

To extend the lifespan of your wire wheel brush, clean it regularly to remove debris and prevent rust buildup. Store it in a dry, cool place and inspect it for wear before each use. Replacing worn-out brushes promptly will help maintain their effectiveness and ensure a safer working environment.