Sisällysluettelo

Johdanto

In the food production industry, ensuring cleanliness and hygiene is essential to producing safe and high-quality products. One of the tools that play a crucial role in maintaining these standards is the food-grade roller brush. These brushes are designed to clean and remove contaminants from conveyor belts, machinery, and other surfaces that come in direct contact with food. By utilizing food-grade roller brushes, manufacturers can improve both the safety of their products and the efficiency of their operations.

This guide will explore the key benefits of using food-grade roller brushes, how to choose the right brush for your facility, and best practices for maintenance to maximize their longevity and effectiveness.

What Are Food Grade Roller Brushes?

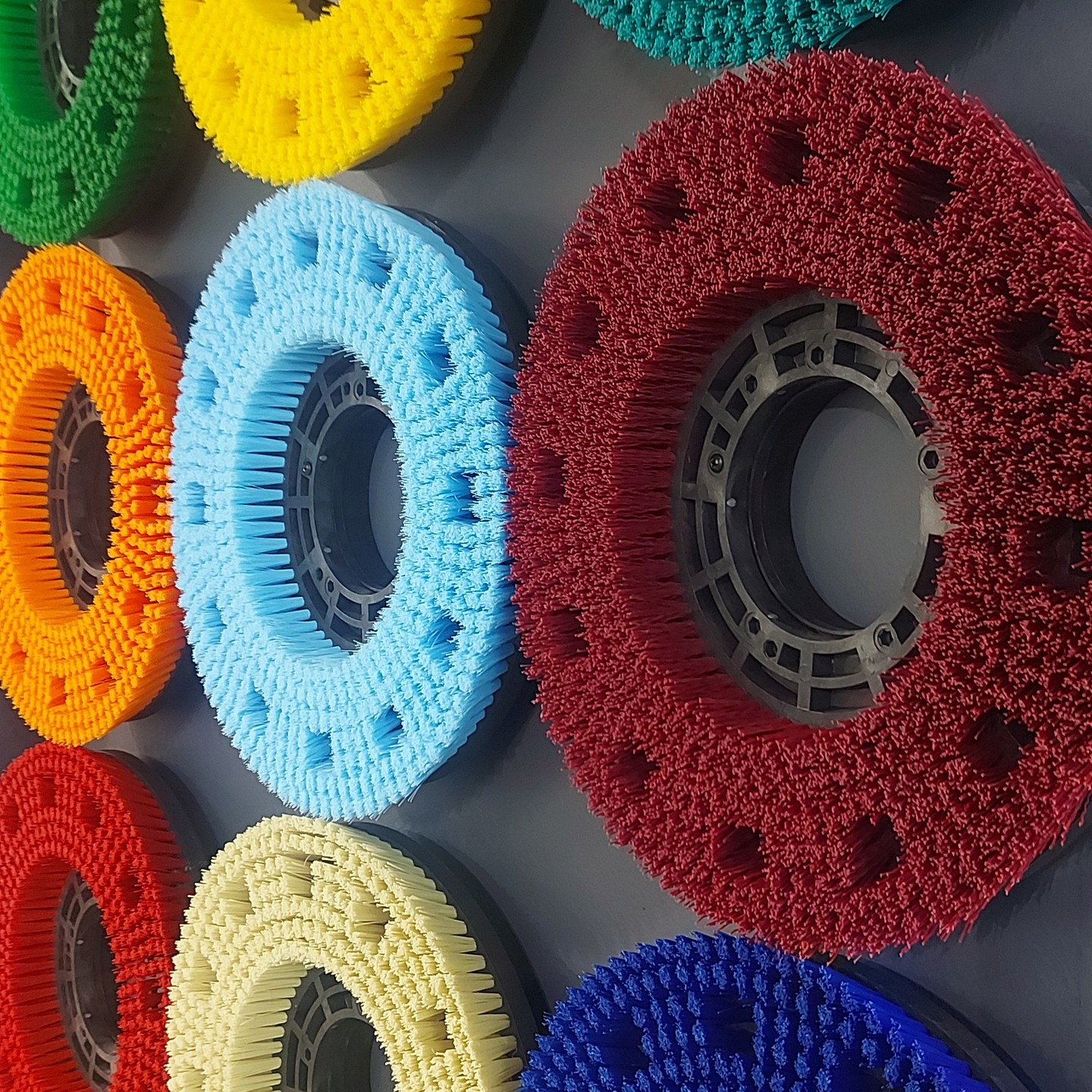

Food-grade roller brushes are specialized cleaning tools designed specifically for environments where food is produced or processed. These brushes consist of durable bristles mounted on a roller, and they are used in production lines and machinery to remove debris, food particles, and contaminants that could pose a risk to food safety. Unlike standard industrial brushes, food-grade roller brushes are made from materials that are safe for contact with food, such as nylon, polypropylene, and other non-toxic, food-safe materials.

Food-grade roller brushes are often used on conveyor belts, sorting machines, and other equipment that come into direct contact with food items. Their design ensures that they can reach deep into crevices, effectively cleaning surfaces while ensuring no harmful residues are left behind.

Key Benefits of Using Food Grade Roller Brushes

Food-grade roller brushes offer a wide array of benefits, particularly in food processing and manufacturing settings. Here are some of the most notable advantages:

1. Enhanced Food Safety

Food safety is a top priority in the food and beverage industry, and food-grade roller brushes are specifically designed to improve hygiene in manufacturing facilities. The materials used in these brushes are safe for direct contact with food, preventing contamination during cleaning. Additionally, these brushes are designed to prevent the growth of bacteria and other microorganisms, reducing the risk of foodborne illness and ensuring compliance with health and safety regulations.

By regularly cleaning production lines and equipment with food-grade roller brushes, manufacturers can ensure that their processes meet the stringent safety standards required in the food industry.

2. Increased Efficiency in Cleaning

Traditional cleaning methods can be time-consuming and labor-intensive, especially when cleaning large surfaces like conveyor belts or sorting machines. Food-grade roller brushes, however, can cover large areas quickly and effectively, reducing the time and labor required for routine cleaning tasks. Their ability to clean efficiently allows manufacturers to keep production lines running smoothly and minimize downtime due to cleaning procedures.

Moreover, food-grade roller brushes can be custom-designed to fit the specific dimensions of different machinery or surfaces. This ensures that the brushes work optimally, making cleaning tasks even more efficient.

3. Longer Lifespan and Durability

One of the key benefits of food-grade roller brushes is their longevity. These brushes are made from high-quality, durable materials that can withstand the demands of heavy usage and exposure to harsh cleaning chemicals. As a result, food-grade roller brushes typically have a longer lifespan than standard cleaning brushes, which helps to reduce the need for frequent replacements and saves on maintenance costs over time.

In addition to their durability, these brushes are designed to resist wear and tear, maintaining their cleaning performance even after extended use.

4. Cost Savings

Although food-grade roller brushes may have a higher initial cost compared to traditional cleaning brushes, their durability and efficiency provide long-term cost savings. With fewer replacements needed and less time spent on cleaning tasks, these brushes provide excellent value over time. Investing in food-grade roller brushes can lead to a significant reduction in labor costs and a lower overall cost of ownership in the long run.

How to Choose the Right Food Grade Roller Brush

Choosing the appropriate food-grade roller brush for your facility requires consideration of several factors, including the type of machinery, the specific cleaning requirements, and the materials involved. Here are some key factors to keep in mind when selecting the right brush:

1. Brush Type and Size

Food-grade roller brushes come in various shapes, sizes, and bristle configurations to suit different tasks. The type of brush you select will depend on the type of machinery or surface you need to clean. For example, softer bristles may be needed for cleaning delicate surfaces, while stiffer bristles are required for heavy-duty cleaning tasks. Some roller brushes are designed to clean large surfaces, while others are better suited for smaller, more intricate areas.

Be sure to select a brush that is designed for your specific needs to ensure optimal performance.

2. Material Selection

The materials used in food-grade roller brushes are critical to their effectiveness and safety. Common materials include nylon, polypropylene, and stainless steel. Nylon and polypropylene are both highly durable and resistant to wear, while stainless steel may be used for more heavy-duty applications.

Consider the type of food products being produced in your facility when selecting the brush material. For example, if you are working with acidic food products, polypropylene may be a better choice due to its resistance to corrosion.

3. Compatibility with Cleaning Chemicals

In many manufacturing facilities, cleaning chemicals are regularly used to maintain hygiene standards. When choosing a food-grade roller brush, it’s important to consider the types of cleaning chemicals your facility uses. Some chemicals can degrade certain materials, so it’s important to choose a brush that is compatible with the chemicals in use to ensure that the brush remains effective over time.

4. Brush Performance

Another consideration is the brush’s performance in terms of cleaning power. Food-grade roller brushes are available with varying levels of stiffness, which affects their ability to scrub and clean. A softer brush may be appropriate for delicate surfaces, while a more aggressive brush may be required for removing stubborn debris or grease. Selecting the right bristle stiffness is crucial for effective cleaning.

Tips for Proper Maintenance and Cleaning of Food Grade Roller Brushes

To extend the life and maintain the performance of your food-grade roller brushes, it’s essential to follow proper maintenance and cleaning procedures. Here are some helpful tips:

1. Regular Cleaning

Food-grade roller brushes should be cleaned regularly to prevent the buildup of debris and contaminants. After each use, rinse the brush with warm water and mild detergent to remove any food particles or residues. Using a degreaser can also help to break down oils or grease that may have accumulated on the bristles.

2. Proper Storage

Store food-grade roller brushes in a clean, dry environment to prevent exposure to moisture, which could promote bacterial growth. Keep them away from direct contact with food products, chemicals, or any other potential contaminants.

3. Inspection and Replacement

Inspect food-grade roller brushes frequently to ensure they are not damaged, worn, or frayed. If the bristles show signs of wear or the brush becomes ineffective at cleaning, it’s time to replace it. Regular inspections can prevent brushes from failing during use and ensure that cleaning tasks continue smoothly.

Two Extra Features of Food Grade Roller Brushes

1. Customization Options for Specific Applications

One of the advantages of food-grade roller brushes is their customizability. Many manufacturers offer custom brush sizes, bristle types, and configurations, allowing you to select a brush that fits your specific machinery or production line. Custom brushes can improve cleaning efficiency by ensuring that the brush fits perfectly into the space it needs to clean.

2. Resistance to Harsh Environments

Food-grade roller brushes are designed to withstand the demanding conditions of food manufacturing environments. Whether exposed to high temperatures, moisture, or harsh cleaning chemicals, these brushes are built to resist wear and maintain their cleaning power over time. This makes them reliable for long-term use in food production facilities.

Johtopäätös

Food-grade roller brushes are essential tools in maintaining hygiene and efficiency in the food and beverage manufacturing industry. Their ability to effectively clean machinery and surfaces, coupled with their durability and cost-effectiveness, makes them an invaluable asset to any production facility. By selecting the right brush for your needs and following proper maintenance procedures, you can ensure that your production line remains clean, safe, and compliant with industry standards.

Investing in high-quality food-grade roller brushes will not only improve the cleanliness and safety of your facility but also help streamline your operations, saving time and money in the long run.

Usein kysytyt kysymykset (UKK)

1. What materials are food-grade roller brushes typically made from?

Food-grade roller brushes are typically made from materials such as nylon, polypropylene, and stainless steel. These materials are safe for food contact and are designed to withstand the harsh conditions found in food manufacturing environments.

2. How often should food-grade roller brushes be replaced?

Food-grade roller brushes should be replaced when they show signs of wear, such as frayed bristles or a decrease in cleaning efficiency. Regular inspections should be performed to ensure the brushes are in good condition, and replacement should occur before they fail during use.

3. Can food-grade roller brushes be used with all types of food products?

Food-grade roller brushes are designed for use with various food products, but the specific brush material should be selected based on the type of food being produced. Consider factors like acidity and temperature when choosing the right brush to ensure compatibility and avoid contamination.