Sisällysluettelo

Johdanto

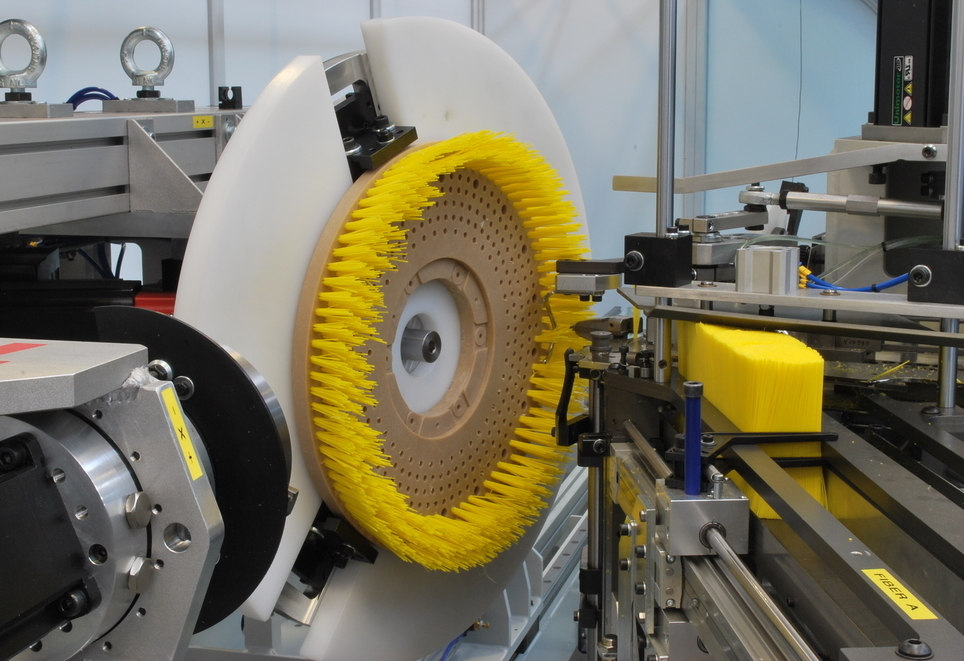

Tube cleaning brushes play an essential role in maintaining the efficiency, longevity, and hygiene of equipment used in industries ranging from manufacturing to pharmaceuticals. These brushes are specifically designed to clean the inner surfaces of tubes, removing dirt, debris, scale, and other contaminants that can accumulate over time. With their versatility, tube cleaning brushes are critical in ensuring that everything from heat exchangers to medical tubing operates smoothly and safely.

In this guide, we’ll explore the importance of tube cleaning brushes, their applications in various industries, and why regular maintenance is crucial for improving performance and reducing downtime. Whether you’re involved in HVAC systems, food processing, or power generation, you’ll learn how tube cleaning brushes can optimize your operations.

What Are Tube Cleaning Brushes?

At first glance, tube cleaning brushes may appear to be simple tools, but their significance is far-reaching across various industries. Essentially, these brushes consist of cylindrical bristles attached to a handle, allowing for easy manipulation inside tubes and pipes. While their design may be straightforward, their function is crucial.

Tube cleaning brushes come in a variety of sizes, shapes, and bristle materials, which makes them highly adaptable to different types of tubes and the specific debris that may accumulate within them. Their primary purpose is to remove stubborn dirt, grease, bacteria, and contaminants from the interior of tubes, ensuring that the flow of liquids or gases remains uninterrupted.

Why does this matter? Tubes are central to the transportation of substances in many industries. Whether it’s chemicals in a manufacturing plant or vaccines in the medical sector, any contamination within these tubes can compromise product quality, safety, and system efficiency. Tube cleaning brushes help prevent these issues by ensuring that tubes remain debris-free and functional.

Moreover, these brushes are not just for cleaning once a problem has occurred. They are an excellent tool for routine maintenance, which helps to prevent blockages and improve the overall performance of equipment. Regular use of tube cleaning brushes has been shown to enhance production efficiency in several industries.

7 Key Applications of Tube Cleaning Brushes

1. HVAC Systems

HVAC (heating, ventilation, and air conditioning) systems rely on tubes to distribute air throughout buildings. Over time, dust, bacteria, and other debris can accumulate inside these tubes, affecting airflow and reducing system efficiency. Tube cleaning brushes are vital for maintaining the cleanliness of HVAC systems. They help improve indoor air quality, enhance system performance, and extend the lifespan of HVAC equipment.

2. Boilers

Boilers are commonly used to generate steam or hot water for heating or industrial applications. The tubes within these boilers can develop scale buildup due to heat and pressure. This scale reduces the boiler’s ability to transfer heat efficiently, which in turn lowers overall performance. Tube cleaning brushes are crucial for removing scale, improving heat transfer, and ensuring the boiler operates at optimal efficiency.

3. Refrigeration Systems

Refrigeration systems use tubes to circulate refrigerant and maintain cooling. Over time, these tubes can become clogged with oil, ice, or other debris, which negatively affects the system’s efficiency. Tube cleaning brushes are highly effective in removing these deposits and restoring the system’s performance. Regular maintenance with tube cleaning brushes can help reduce energy consumption and increase the overall lifespan of refrigeration systems.

4. Oil and Gas Industry

In the oil and gas sector, tubes are used in a variety of equipment, including heat exchangers, condensers, and boilers. Rust, scale, and other contaminants can build up inside these tubes, leading to corrosion and reduced system performance. Tube cleaning brushes are critical for maintaining these tubes, ensuring that equipment runs smoothly and efficiently, and preventing costly breakdowns and repairs.

5. Food and Beverage Industry

The food and beverage industry frequently relies on tubes for processes such as pasteurization, cooking, and packaging. These tubes can become contaminated with food particles, bacteria, and other debris, which can pose a risk to food safety. Tube cleaning brushes are essential for keeping these tubes clean and hygienic, ensuring that products are safe for consumers and comply with health regulations.

6. Pharmaceutical Industry

The pharmaceutical industry requires tubes for various processes such as distillation, filtration, and sterilization. These tubes must remain free from contaminants, bacteria, and other impurities to ensure the safety and efficacy of drugs and medical devices. Tube cleaning brushes are indispensable for maintaining the cleanliness of these tubes, preventing contamination, and supporting the production of safe and effective pharmaceutical products.

7. Power Generation Industry

Power generation facilities use tubes in heat exchangers, condensers, and boilers. These tubes are essential for the efficient transfer of heat and energy. However, scale buildup, corrosion, and other deposits can quickly degrade the performance of these components. Tube cleaning brushes are essential for maintaining the efficiency and reliability of power generation equipment, reducing the risk of failures, and extending the lifespan of vital components.

Why Regular Tube Cleaning is Vital for Performance

Regular tube cleaning is not only important for hygiene but also for maintaining optimal performance across all industries. Over time, tubes accumulate scale, rust, dirt, and debris, which can lead to blockages, corrosion, and decreased efficiency. If left unchecked, this buildup can result in costly downtime, system failures, and reduced product quality.

Routine maintenance with tube cleaning brushes helps to remove these contaminants, ensuring that systems operate efficiently. It also helps extend the lifespan of the equipment, reducing the need for costly repairs or replacements. By investing in regular tube cleaning, industries can prevent issues before they arise, resulting in higher productivity and lower operational costs.

Johtopäätös

Tube cleaning brushes are indispensable tools in many industries, from manufacturing to pharmaceuticals. By keeping tubes clean and free from contaminants, these brushes help to maintain the efficiency and longevity of equipment, reduce the risk of failures, and improve overall performance. Regular tube cleaning is essential for preventing buildup that can cause damage and inefficiency.

With a variety of tube cleaning brushes available, selecting the right brush for your specific needs is crucial for maintaining your equipment’s performance. By implementing a regular cleaning routine, industries can significantly improve their ROI, reduce maintenance costs, and enhance the overall reliability of their operations.

Usein kysytyt kysymykset

1. What types of materials are used in tube cleaning brushes?

Tube cleaning brushes are typically made from materials such as stainless steel, brass, nylon, or wire, depending on the type of tube and debris buildup. Steel or brass bristles are ideal for heavy-duty applications, while nylon is better for light-duty cleaning.

2. How often should tube cleaning brushes be used in industrial settings?

The frequency of tube cleaning depends on the specific industry and the amount of buildup in the tubes. Generally, regular cleaning every few weeks to months is recommended to prevent the accumulation of debris and to maintain system efficiency.

3. Can tube cleaning brushes be used on all types of tubes?

Tube cleaning brushes are available in various sizes and designs, making them suitable for a wide range of tubes, including those used in HVAC systems, boilers, refrigeration units, and medical applications. Choosing the right brush depends on the tube size, material, and type of buildup that needs to be cleaned.