- Home

- Products

- Industrial Brushes

- Wholesale High Temperature Resistant Cement Brick Machine Wire Brush

Wholesale High Temperature Resistant Cement Brick Machine Wire Brush

Product Specifications

| Attribute | Details |

|---|---|

| Product Name | High Temperature Resistant Brush Seal Row Strip Brush Cement Brick Machine Steel Wire Brush |

| Model Number | WTB-VIROS008 |

| Brand Name | VIROS |

| Type | Industrial Brush |

| Place of Origin | Anhui, China |

| Grade | Industrial |

| Warranty | 1 Year |

| Customized Support | OEM, ODM |

| Brush Material | Steel / Brass / Nylon / Customized |

| Function | Cleaning / Polishing / Rust Removal |

| Color | Yellow / Gray / Customized |

| Trim Length | 5 – 250 mm (customizable) |

| Bristle Length | Customized |

| Overall Length | Customized |

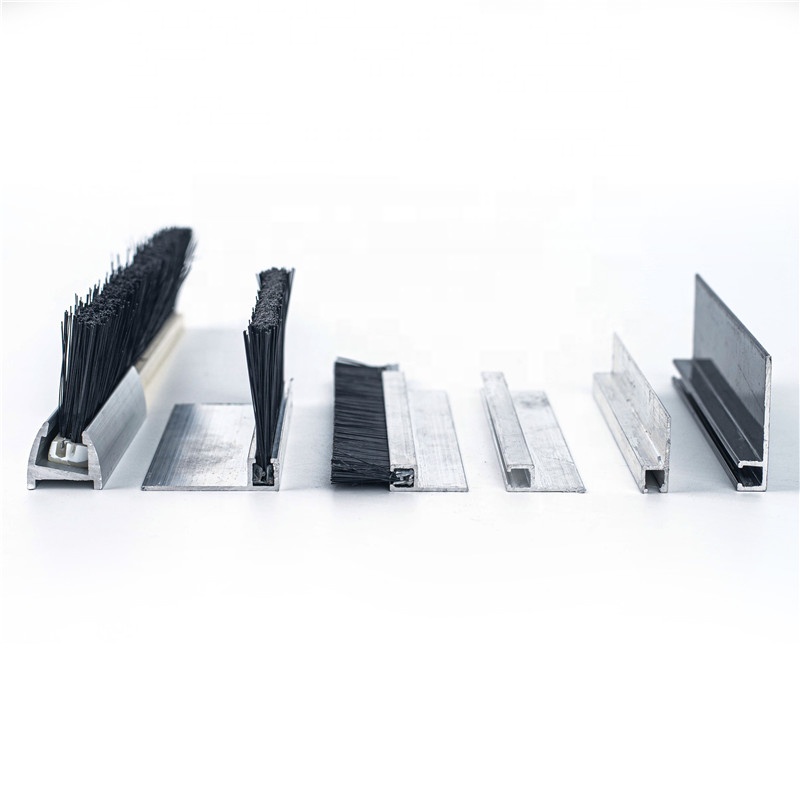

| Holder Style | T / H / F-shape or Customized |

| Application | Cleaning, Polishing, Rust Removal |

| Sample | Available |

| MOQ | 20 Meters |

| Package | Hard Cardboard Box / Plywood Case / Pallet |

Product Details

High Temperature Resistant Wire Brush for Cement Brick Making Machines – Wholesale Industrial Supply

Heavy-Duty Wire Brush Engineered for Cement Brick Production

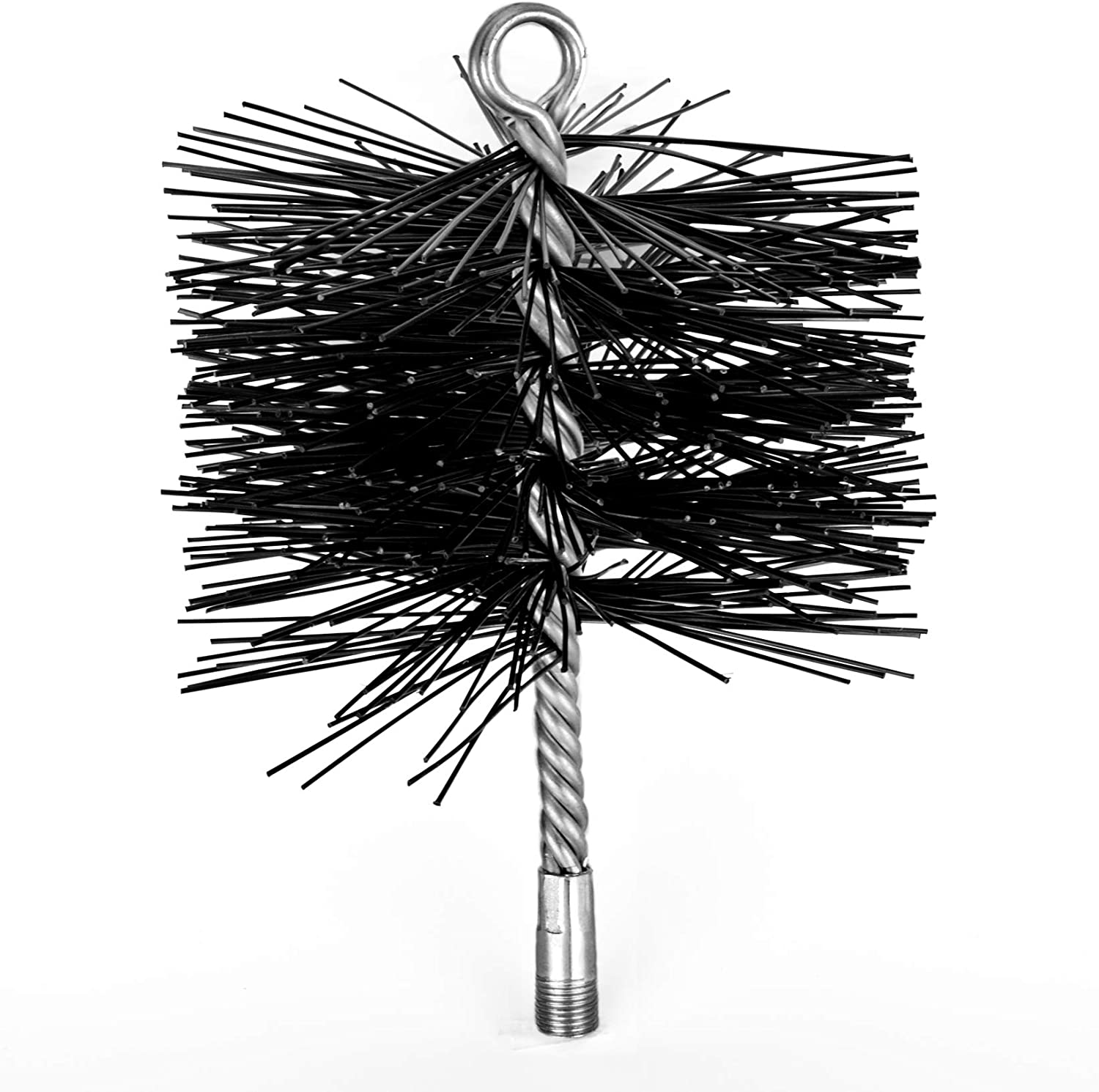

The High Temperature Resistant Cement Brick Machine Wire Brush is designed for industrial-grade brick manufacturing environments where durability, heat resistance, and consistent surface cleaning are essential. Constructed from high-tensile steel or stainless wire and mounted in a strong metal channel, this wire brush is optimized for use in cement brick pressing, molding, and demolding applications.

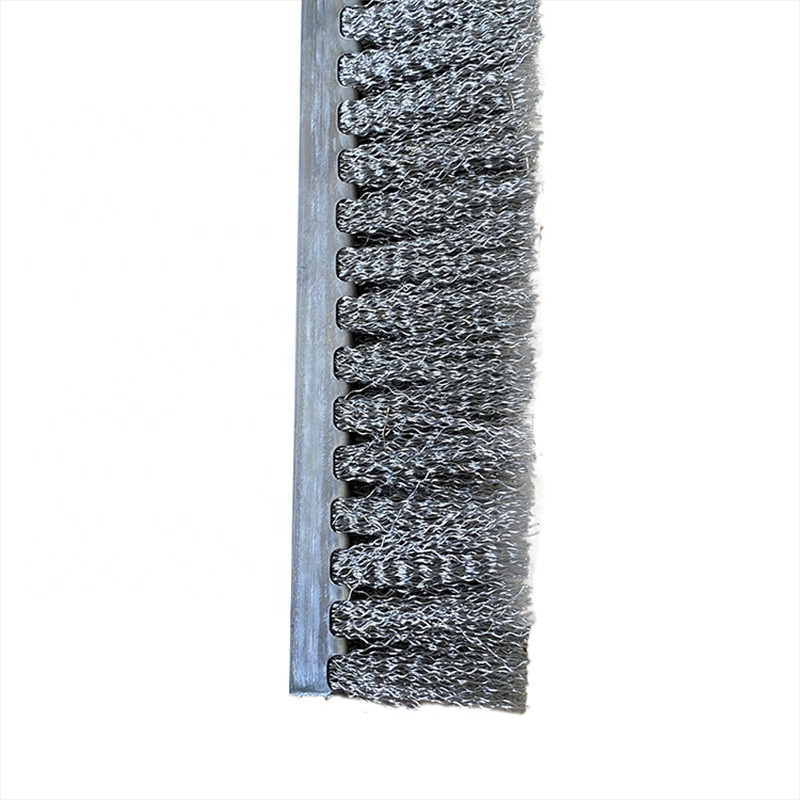

Durable Construction for Extreme Industrial Conditions

This brush is manufactured with densely packed crimped wire bristles, known for their stiffness and long wear life. The wires are securely fixed into a U-shaped galvanized or stainless steel backing strip, ensuring maximum bristle retention during high-friction operation. Designed to withstand temperatures commonly found in hydraulic brick press machines and continuous production lines, the brush performs reliably in hot, dusty, and abrasive environments.

Its robust structure and wear-resistant properties help keep mold surfaces clean from concrete residue, dust, and buildup, improving the precision and quality of brick edges and surfaces.

High Temperature and Corrosion Resistance

A key feature of this cement brick machine wire brush is its ability to perform under elevated temperatures and harsh chemical exposure. The high-carbon steel or stainless wire maintains structural integrity even under continuous contact with hot cement slurry, vibration, and mold-release agents.

This makes it ideal for use in:

- Hydraulic cement brick making machines

- Automatic concrete block production lines

- High-speed tile and paver forming equipment

- Demolding stations in refractory material factories

Custom Sizes and Bristle Options

Available in a wide range of lengths, bristle heights, and wire thicknesses, our wire brushes can be tailored to fit specific machine brands and mounting tracks. Common customization options include:

- Wire Material: High-carbon steel, stainless steel (SS304/316)

- Bristle Type: Crimped or straight wire

- Bristle Height: 20mm–100mm

- Backing Strip: Galvanized iron or stainless steel channels

- Mounting Options: Press-fit, bolted, or magnetic base

We also support custom punching, shaping, or pre-cutting to match your production line’s technical requirements.

Benefits in Brick Manufacturing Applications

Integrating this wire brush for cement brick machines into your workflow brings multiple production and maintenance advantages:

- Reduces buildup of cement and dust on critical machine surfaces

- Improves mold longevity and reduces downtime due to contamination

- Maintains clean, crisp edges on bricks and blocks

- Minimizes manual cleaning and labor intensity

- Resists deformation under mechanical and thermal stress

Used in Automated and Manual Equipment

Whether your factory uses fully automated block presses or semi-automatic cement tile machines, this high-temperature industrial wire brush can be adapted for integration. It can be fixed directly to demolding arms, mold walls, side scrapers, or conveyor cleaning units.

This makes it a flexible tool for continuous-use environments such as:

- Construction material manufacturing plants

- Refractory brick production lines

- Concrete paver factories

- Fly ash brick machines

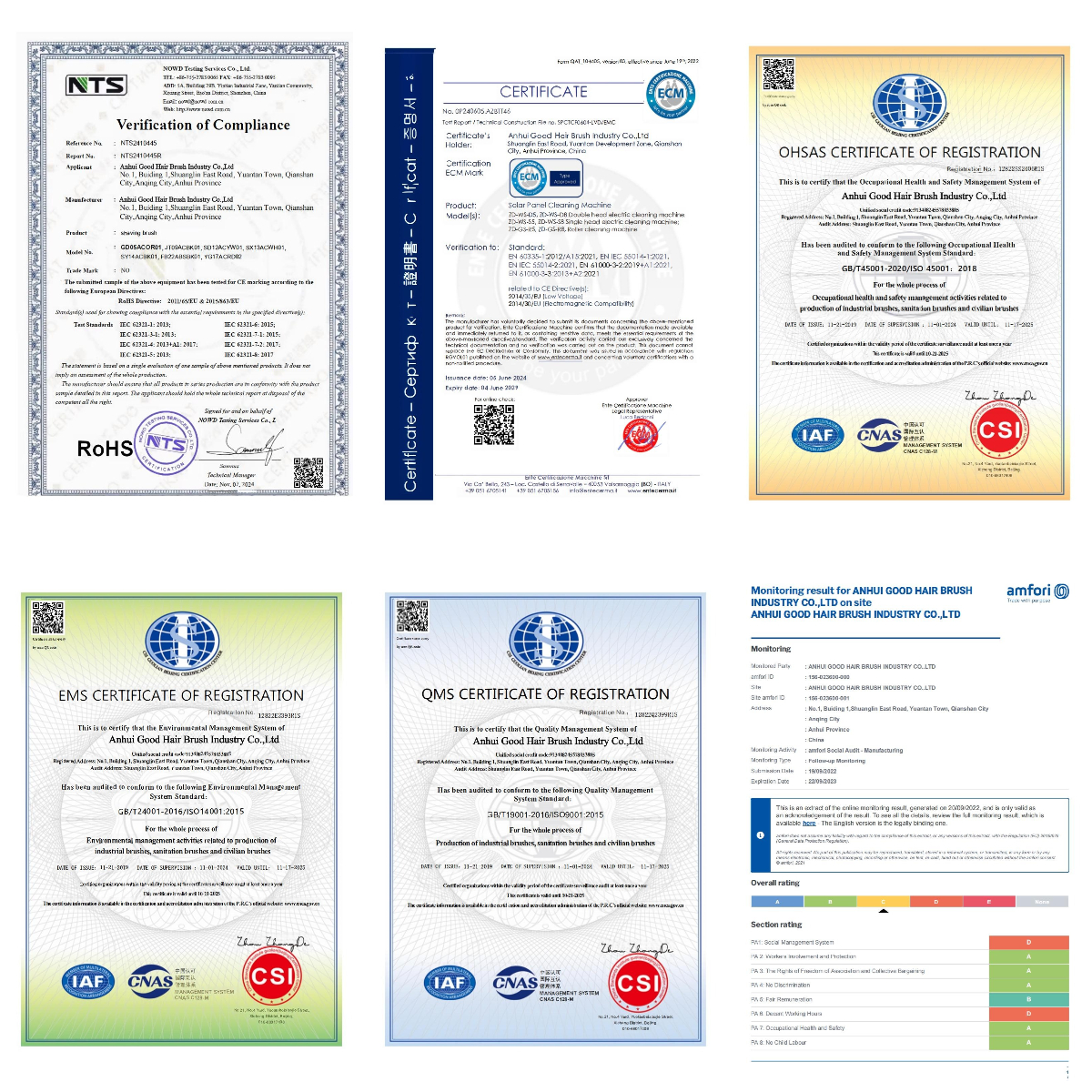

Quality Assurance and Wholesale Supply

Each wire brush undergoes strict quality checks for bristle pull strength, channel integrity, and dimensional tolerance. We offer bulk wholesale packaging with customizable branding, part labeling, and carton marking for distributors and OEM partners.

With over 10 years of experience in manufacturing brushes for construction machinery, we ensure consistent performance, competitive pricing, and fast delivery worldwide.

Order Today – Get a Reliable Cleaning Solution for Your Brick Machine

If you’re seeking a durable, temperature-resistant, and precision-engineered wire brush for cement brick machine cleaning, our products are trusted by hundreds of manufacturers globally. Request a sample, technical spec sheet, or custom quotation today.

Keep your brick molds clean, your output sharp, and your equipment efficient — all with our industrial-grade wire brush solutions.

Custom industrial brush Services

As a professional industrial brush manufacturer, our goal is to provide comprehensive solutions to meet your needs.

Cutom Logo

We offer a full suite of custom-branding options—precision laser engraving, vibrant silk-screen printing and high-quality hang-tags Simply send us your artwork or design file, let us tailor a solution that perfectly reflects your cleaning brush brand’s identity and style.

Custom Materials

We support a wide range of customizations for cleaning brush materials, we can tailor every detail to match your specific requirements. All materials used are eco-friendly, ensuring safety, durability, and a commitment to environmental responsibility.

Custom Shapes

Various cleaning brush bristles are available to meet your different needs, whether you require soft, medium, or firm textures. Each type is carefully selected to ensure optimal performance for a wide range of applications.

Personalized Handle

We offer personalized handle options to give your brushes a unique and professional look. From shape and size to color and finish, every detail can be customized to match your brand identity or functional preferences.

Custom Packaging

We provide custom cleaning brush packaging solutions to enhance your brand presentation and product appeal—from eco-friendly kraft boxes to printed gift packaging and hangtags—all designed to reflect your brand style and values.

Your Trusted industrial Brush Manufacturer

From idea to product, we turn your vision into reality through professional product knowledge and craftsmanship.

Industry Leadership

GH Brush is one of the world’s leading companies in brush design and manufacturing. Our expertise spans a wide range of products, from Industrial brushes to brushes for Makeup Brushes. We adapt our operations to meet each customer’s specific needs, offering competitive pricing, fast delivery times, and world-class manufacturing quality.

Global Logistics

All of our brushes are manufactured in the China, giving us an ideal geographic position to serve customers around the world quickly. Our global customer base ranges from emergency airfreight orders to full 40-foot container shipments.

Cutting-Edge Technology

Our production facilities are equipped with the most advanced brush-making equipment. All materials are of the highest quality and are carefully selected by experts to meet every specific demand.

Expertise

With years of expertise in industrial brush manufacturing, our team possesses deep knowledge of materials, brush design, and production techniques. We understand the nuances of different bristle types, handle ergonomics, and finishing processes to create brushes that deliver superior performance and comfort. This expertise enables us to innovate continuously and tailor solutions that meet the evolving needs of professionals and brands worldwide.

We’re here to tailor our premier brushes services to your unique needs with brush services.

custom high-quality brushes for 20 years

AnHui Good Hair Brush Co., Ltd. was established in 2005, specializing in the sale and service of all kinds of ccosmetic brushes, cleaning brushes, industrial brushes, bamboo brushes. The company is located in Anhui, which has convenient transportation. In order to provide the best quality products and services, we have established a modern quality management system that strictly follows international standards. Our customers are all over the world, especially in North America, Europe, Africa, Southeast Asia and Australia. We adhere to the business principle of mutual benefit and have won a good reputation among our customers with perfect service, high-quality products and very competitive prices. We also accept OEM and ODM services as well as small orders. Since starting business in 2005, Good Hair Brush has been committed to creating high-quality products and bringing you a personalized service experience throughout the process. From concept design to production packaging, Good Hair Brush always pays attention to details throughout the production process. No matter what the purpose, Good Hair Brush can produce high-quality brushes that exceed all your expectations.

We treat your business as our own, with “growing together” as our core value, and we are dedicated to earning your trust. GH Brush faces the challenges of a competitive and ever-evolving market by staying attuned to the needs of the industry and adapting to the world around us. As a responsible partner to our customers, suppliers, and communities, we uphold strict quality assurance standards and provide fast, professional service. We are committed to delivering innovative brush solutions and consistently exceeding our customers’ expectations with superior craftsmanship and attention to detail.

Frequently Asked Question

Q1:May I take some samples to test before placing the order ?

A:Yes, we can send you some pcs free samples, but need you pay the shipping cost. after received the samples welcome to contact with us anytime.

Q2:Can you give me a discount for the products ?

A:We mainly do wholesale service, our policy is that bigger quantity,cheaper price, so we will quote you the best price based on your order quantity.

Q3:How long can you offer the samples ?

A:1~3 days after we confirmed the order you paid.

Q4:Can you offer Customer Service after sales ?

A:We can provide professional customer service after you place the order.

Q5:How long will it take to receive my order?

A: This will depend on your quantity and the product, OEM product time about 30-35days. Ready to ship product will be in 15days

Q6: What is your patment term?

A:Our payment term is 40% deposit, 60% balance,we accpet alibaba trade assurance, T/T bank transfer;WestUnion;Money gram and Paypal.