Table of Contents

Introduction to Brass Wire Brushes

When tackling a range of cleaning, polishing, and maintenance tasks, having the right tool is essential. Brass wire brushes are often the go-to choice in many industries for handling metal surfaces delicately and efficiently. These brushes, featuring bristles made from a brass alloy, offer several unique benefits compared to other materials like steel or nylon. Brass wire brushes are gentle enough to clean surfaces without causing damage while being effective at removing rust, dirt, grime, paint, and other buildups. They are used in various applications, from preparing surfaces for painting to cleaning intricate metal components, and their non-sparking nature makes them particularly useful in hazardous environments.

In this article, we will explore the features, benefits, and diverse applications of brass wire brushes. We’ll look at why they are essential in specific industries, provide tips on selecting the right brush for your needs, and highlight how to maintain them for long-lasting performance. Additionally, we will address some frequently asked questions to provide a deeper understanding of these versatile tools.

What is a Brass Wire Brush?

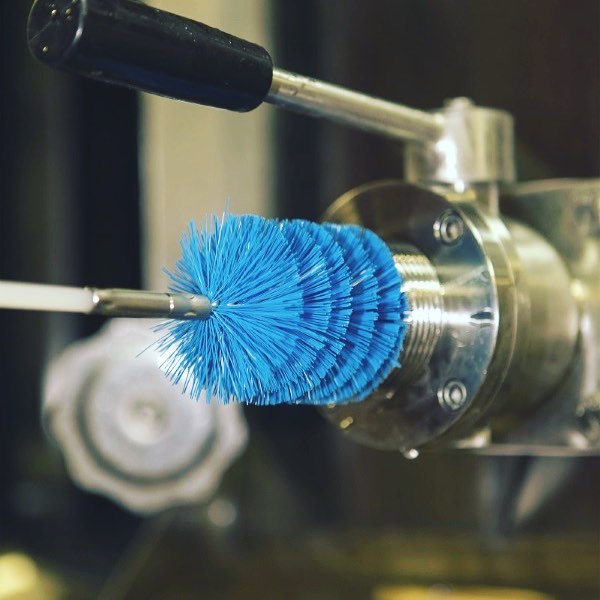

A brass wire brush is a tool composed of bristles made from brass, a metal alloy primarily made of copper and zinc. The bristles are typically mounted on a handle or attached to a rotating tool like a drill or grinder for added convenience and efficiency. Brass wire brushes are commonly used in a range of cleaning and maintenance tasks where a gentle yet effective action is required. Their softness compared to harder wire brushes, such as those made from steel, makes them perfect for delicate work that requires precision without scratching or damaging the material being cleaned.

Brass brushes are also prized for their non-sparking properties, making them a safe option in environments where flammable materials may be present. These brushes come in various configurations, including handheld brushes, wheel brushes, and cup brushes, each suited for different applications and types of surfaces. The versatility and reliability of brass wire brushes make them indispensable in industries such as automotive, electrical, marine, and metalworking.

Key Features of Brass Wire Brushes

Brass wire brushes offer several unique characteristics that make them ideal for a range of tasks. Let’s take a look at the features that distinguish them from other wire brushes:

1. Soft Yet Durable Bristles

The brass bristles in these brushes are soft compared to other metals like steel, which makes them perfect for cleaning delicate surfaces without causing scratches or damage. However, brass is still durable enough to handle tough cleaning tasks, providing a good balance of effectiveness and safety. This makes brass wire brushes an ideal choice for a wide range of applications, from automotive maintenance to jewelry cleaning.

2. Non-Sparking Properties

One of the standout features of brass wire brushes is their non-sparking nature. Brass does not generate sparks when used on metal surfaces, making these brushes safe to use in environments where sparks could ignite flammable gases or materials. This property is particularly important in industries such as oil and gas, mining, and chemical manufacturing, where working with highly flammable substances is common.

3. Corrosion Resistance

Brass is naturally resistant to corrosion, making brass wire brushes ideal for use in humid or moist environments. Unlike steel brushes, which can rust over time, brass wire brushes maintain their performance even in wet or corrosive conditions. This extends the lifespan of the brush and ensures that it remains effective even after prolonged use.

4. Electrical Conductivity

Another important feature of brass wire brushes is their electrical conductivity. Brass is a good conductor of electricity, which makes these brushes suitable for use in electrical maintenance. For example, they can be used to clean electrical contacts or terminals, ensuring good conductivity and preventing issues like corrosion or poor electrical flow.

Common Uses of Brass Wire Brushes

Brass wire brushes are used in a variety of applications across different industries. Their versatility and unique properties make them suitable for several tasks, from cleaning and polishing to surface preparation and maintenance. Here are some common uses of brass wire brushes:

1. Surface Preparation

Before applying a new coat of paint, coating, or plating, it is essential to prepare the surface properly. Brass wire brushes are often used in surface preparation to remove rust, dirt, grime, old paint, and other contaminants. Their gentle yet effective cleaning action ensures that the surface is free of debris, allowing for better adhesion of paints, coatings, or other treatments. This is particularly important in automotive, construction, and manufacturing industries, where high-quality finishes are required.

2. Cleaning and Deburring Metal Parts

Brass wire brushes are widely used in metalworking for cleaning and deburring metal parts. When metal is cut, it often leaves behind burrs or sharp edges that can cause injury or prevent parts from fitting together properly. Brass wire brushes can remove these burrs, smooth out rough edges, and clean the parts without damaging the underlying metal. This makes them invaluable in industries where precision and safety are crucial, such as in aerospace and automotive manufacturing.

3. Automotive Maintenance

Brass wire brushes are essential tools in automotive maintenance. They are used to clean spark plugs, battery terminals, fuel injectors, and other components to ensure optimal performance. The soft bristles are ideal for removing corrosion and build-up without damaging sensitive automotive parts. Using a brass wire brush helps maintain the efficiency of the vehicle’s electrical system and engine components, ensuring a longer lifespan for the vehicle.

4. Marine Applications

In the marine industry, brass wire brushes are invaluable for maintaining boat and yacht fittings. They are used to clean metal surfaces, propellers, and other hardware exposed to saltwater, which can cause corrosion and deterioration. The corrosion-resistant properties of brass make these brushes perfect for environments where metal is exposed to harsh saltwater conditions, helping to preserve the integrity of the equipment and reduce maintenance costs.

5. Electrical Maintenance

Brass wire brushes are frequently used in electrical maintenance to clean electrical contacts, terminals, and circuit boards. Their non-sparking properties ensure safety in potentially hazardous environments, while their conductivity aids in maintaining proper electrical connections. Regular use of brass wire brushes helps prevent corrosion and ensures that electrical components function properly, reducing the risk of malfunction and improving the efficiency of electrical systems.

6. Woodworking

While brass wire brushes are typically associated with metalworking, they can also be used in woodworking. These brushes are great for cleaning wood surfaces, particularly when removing old finishes or preparing wood for staining or painting. The brass bristles are gentle enough not to damage the wood, yet effective in removing dirt, grime, and old finishes, making them ideal for woodworking projects.

7. Jewelry Cleaning

In the jewelry industry, brass wire brushes are used to clean metal components and remove tarnish and oxidation. They are particularly effective for cleaning brass, silver, and gold pieces without scratching or damaging the delicate surfaces. Brass wire brushes help restore the shine to jewelry, ensuring that it looks polished and well-maintained.

Advantages of Using Brass Wire Brushes

Brass wire brushes offer several significant advantages, making them an essential tool in various industries. Here are some of the key benefits:

1. Gentle Cleaning

The softness of brass bristles ensures that brass wire brushes can clean surfaces effectively while minimizing the risk of scratching or damaging delicate materials. This makes them ideal for tasks that require gentle handling, such as cleaning jewelry or automotive components.

2. Durability

Brass wire brushes are highly durable and can withstand repeated use without breaking or fraying. Their corrosion resistance ensures that they maintain their performance over time, even when exposed to harsh environments. This makes them a cost-effective solution for tasks that require frequent brush usage.

3. Versatility

Brass wire brushes can be used on a variety of materials, including metals, plastics, wood, and more. Their versatility makes them a valuable addition to any toolkit, capable of handling tasks across different industries and applications.

4. Cost-Effectiveness

Given their durability and effectiveness, brass wire brushes offer great value for money. They can last longer than brushes made from softer materials, reducing the need for frequent replacements. This makes them a cost-effective investment for both professional and DIY use.

Best Practices for Using Brass Wire Brushes

To maximize the effectiveness and lifespan of your brass wire brush, follow these best practices:

1. Choose the Right Brush

When selecting a brass wire brush, consider the specific application. For detailed work or cleaning small parts, a handheld brush may be ideal. For larger surfaces, a cup or wheel brush attached to a power tool can speed up the process.

2. Use Proper Technique

Apply light pressure and use sweeping motions when using a brass wire brush. Avoid pressing too hard, as this can cause the bristles to break and reduce the brush’s effectiveness.

3. Clean the Brush Regularly

After each use, clean the brass wire brush to remove debris and buildup. This will prolong the lifespan of the brush and ensure it continues to perform effectively.

4. Wear Appropriate Safety Gear

Always wear safety goggles and gloves when using brass wire brushes, especially with power tools. This will protect you from flying debris and potential injury.

5. Store the Brush Properly

Store your brass wire brush in a dry, clean area to prevent corrosion. Keeping the brush away from moisture and direct sunlight will help maintain its condition and performance over time.

Extra Features of Brass Wire Brushes

1. Customization Options

Many manufacturers offer customizable brass wire brushes, allowing you to tailor the brush’s size, shape, and bristle density to suit specific tasks. Customization ensures that the brush will provide the best results for your particular needs, whether you’re working on small, intricate parts or large metal surfaces.

2. Compatibility with Power Tools

Brass wire brushes can easily be attached to power tools like drills and grinders, making them even more efficient for large cleaning and polishing tasks. Using a brass wire brush with a power tool can save time and improve the consistency of the cleaning or finishing process.

Conclusion

Brass wire brushes are essential tools in various industries, offering a unique combination of gentleness, durability, and effectiveness. Whether you’re cleaning metal surfaces, preparing them for coating, or maintaining electrical components, these brushes provide a reliable solution. Their non-sparking nature and corrosion resistance make them suitable for use in hazardous environments, while their versatility allows them to handle a wide range of materials and applications. By choosing the right brass wire brush and following best practices for use and maintenance, you can ensure optimal performance and long-lasting results.

Frequently Asked Questions (FAQs)

1. Can I use a brass wire brush on any metal?

Brass wire brushes are suitable for use on most metals, including steel, aluminum, copper, and more. Their soft bristles prevent damage to delicate surfaces while still effectively removing dirt, rust, and paint.

2. Are brass wire brushes safe to use in explosive environments?

Yes, brass wire brushes are non-sparking, making them safe for use in environments where flammable gases or materials are present. This is one of the key advantages of using brass brushes over other materials like steel.

3. How do I clean and maintain my brass wire brush?

To maintain your brass wire brush, clean it after each use to remove debris and buildup. Store it in a dry, cool place to prevent corrosion. Regular maintenance ensures the brush performs optimally for a long time.