جدول المحتويات

مقدمة

In the world of industrial operations, cleanliness and efficiency are paramount. Industrial cleaning brushes play a vital role in ensuring smooth operations, reducing maintenance costs, and maintaining hygiene across various sectors. From cleaning hard-to-reach spots to polishing surfaces, these brushes are indispensable for a wide range of applications. However, with numerous options available, choosing the right industrial cleaning brush can be a daunting task.

In this comprehensive guide, we’ll walk you through the various types of industrial cleaning brushes, the critical factors to consider when selecting one, and how to choose the ideal manufacturer to meet your specific needs. Whether you’re in manufacturing, food processing, or power plants, this guide will help you make an informed decision.

Types of Industrial Cleaning Brushes

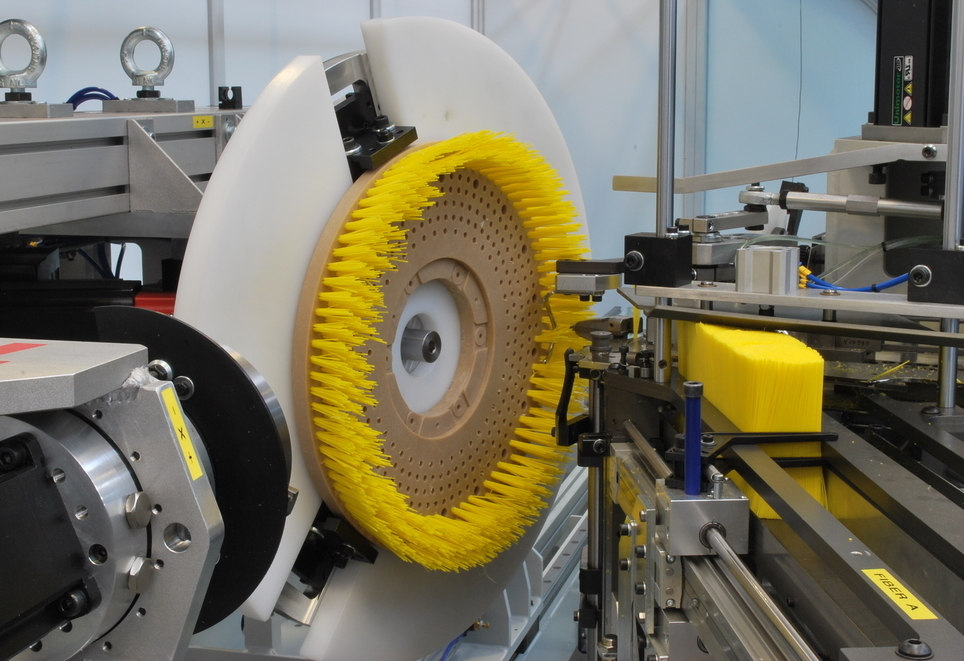

1. Disc Brushes

Disc brushes are designed as circular units that are mounted on rotating machinery to clean, deburr, or polish surfaces. They are commonly used in industries like metalworking, woodworking, and conveyor belt cleaning. Their bristles, which can be made from wire, nylon, or abrasive materials, are tailored to the specific cleaning tasks at hand.

2. Boiler Tube Cleaning Brushes

Boiler tube cleaning brushes are crucial for maintaining the efficiency of heat exchange systems. They are designed to remove soot, scale, and deposits from boiler tubes, ensuring that the system functions smoothly and efficiently. These brushes are typically constructed with durable stainless steel or brass bristles to withstand the extreme temperatures of boiler environments.

3. Tube Brushes

Tube brushes, also known as bottle brushes, are ideal for cleaning cylindrical surfaces like pipes, tubes, and narrow cavities. They are available in different sizes and with various bristle materials, such as nylon, steel, or brass, depending on the cleaning needs. These brushes are widely used in industries such as pharmaceuticals, food processing, and automotive manufacturing.

Key Factors to Consider When Choosing an Industrial Cleaning Brush

1. Material of the Bristles

The material of the brush bristles plays a critical role in its effectiveness and longevity. Common materials include:

- نايلون: Best suited for light-duty cleaning and offers resistance to chemicals.

- Wire (Steel/Brass): Ideal for heavy-duty applications like rust removal and metal polishing.

- Abrasive: Perfect for surface finishing and deburring tasks.

2. Size and Shape of the Brush

It’s crucial to select the right size and shape to match the equipment and areas that require cleaning. A brush that is too large or too small can result in ineffective cleaning and additional maintenance.

3. Durability and Longevity

Industrial brushes are subjected to continuous wear and tear. Opting for high-quality brushes made from durable materials will ensure long-lasting performance, which ultimately saves on replacement costs.

4. Application-Specific Requirements

Determine whether your brush needs to work in dry or wet conditions, high temperatures, or abrasive environments. The specific application will help guide the choice of material, size, and design.

Applications of Industrial Cleaning Brushes Across Various Industries

Different industries rely on industrial cleaning brushes to ensure efficiency, hygiene, and smooth operations. Here’s a breakdown of key sectors where these brushes are widely used:

- Manufacturing & Metalworking: Disc brushes are commonly used for deburring, surface finishing, and rust removal.

- معالجة الأغذية: Hygiene is crucial in food processing, where specialized brushes are used for cleaning conveyor belts and food-grade equipment.

- Pharmaceutical & Healthcare: Tube brushes are essential for cleaning medical tubes and lab equipment, ensuring cleanliness and sterility.

- Automotive & Aerospace: In these industries, brushes are used to clean and polish parts like engine components and aircraft components.

- Power Plants & Boilers: Boiler tube cleaning brushes ensure the efficient operation of heat exchange systems by removing soot, scale, and other deposits.

How to Choose the Right Brush Manufacturer

1. Experience and Expertise

Choose manufacturers who have a proven track record in producing high-quality industrial brushes for various applications. Their experience will ensure that they can provide effective solutions for your specific requirements.

2. Customization Options

A reputable manufacturer should offer customized brush solutions tailored to the unique needs of your industry. Look for companies that provide various bristle materials, sizes, and shapes to meet specific demands.

3. Quality Control and Assurance

Ensure that the manufacturer adheres to strict quality control measures. High-quality brushes made from durable materials will perform better and last longer, saving you costs in the long term.

4. Customer Reviews and After-Sales Support

Investigate customer reviews and testimonials to understand the manufacturer’s reputation. Additionally, good after-sales support is essential to address any issues or questions that arise post-purchase.

خاتمة

Selecting the right industrial cleaning brush is vital for ensuring smooth operations, reducing downtime, and improving productivity across various industries. By considering factors such as brush material, size, durability, and the specific application, you can choose the ideal brush for your needs. Furthermore, partnering with a reliable and experienced brush manufacturer will provide you with high-quality solutions that stand the test of time.

Investing in the right industrial cleaning brush not only enhances cleaning efficiency but also contributes to cost savings and operational excellence. Take the time to select the best brush and manufacturer for your business, and enjoy the long-term benefits of superior performance.

الأسئلة الشائعة

1. What types of bristles are best for heavy-duty industrial cleaning?

For heavy-duty cleaning, wire bristles (steel or brass) are typically the best choice due to their strength and durability, making them ideal for tasks like rust removal and metal polishing.

2. Can industrial cleaning brushes be used in high-temperature environments?

Yes, certain types of brushes, especially those with stainless steel or brass bristles, are designed to withstand high temperatures. These are particularly useful in industries like power plants and boilers.

3. How do I know which size brush to choose for my equipment?

The size of the brush should match the area you need to clean. A brush that is too large or too small for the equipment may not perform effectively. Always consider the specific requirements of your machinery when selecting a brush size.